How Premier Aluminum Llc can Save You Time, Stress, and Money.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Blog Article

Some Known Details About Premier Aluminum Llc

Table of ContentsThe smart Trick of Premier Aluminum Llc That Nobody is Talking AboutFacts About Premier Aluminum Llc RevealedThe Definitive Guide for Premier Aluminum LlcThings about Premier Aluminum LlcA Biased View of Premier Aluminum Llc

When selecting a light weight aluminum factory for your production demands, it's vital to study numerous factors. One of the most vital aspects to take into consideration is the experience and skills of the shop. Picking a factory that has the appropriate understanding of the light weight aluminum casting procedure, and the portfolio to show for it, helps to have an effective result for your job.Having the experience and industry knowledge to engineer your castings for ideal manufacturing and high quality results will certainly enhance the job. Making light weight aluminum castings needs a complex set of processes to attain the right results. When choosing a new aluminum factory to companion with, guarantee they have considerable sector experience and are well-informed about all facets of the aluminum casting process: layout, manufacturing, material analysis, and product screening.

The shop ought to also have a tested performance history of supplying remarkable products that fulfill or go beyond client expectations. Quality assurance must also go to the top of your listing when choosing a light weight aluminum factory. By collaborating with a qualified shop who follows the criteria for top quality control, you can safeguard the integrity of your product and ensure it meets your specifications.

The Facts About Premier Aluminum Llc Revealed

Various parts that really complicated shapes can be manufactured utilizing this process. Prior to you start searching for a dependable light weight aluminum die caster, there are some essential points that you need to do.

You need to ask on your own what kind of light weight aluminum die castings you need. After identifying what you need, you have to specify the requirements of the aluminum pass away castings you require. Determine the weight, thickness, dimension, and various other specifications of the aluminum die-cast you need. It would also be better if you could draw and show all the measurements of the aluminum die-cast.

After having this information, you can begin investigating light weight aluminum die-casting makers. You can do this by simply inputting the key words" Aluminum die casting makers" on the Google search engine.

Some of the inquiries you need to ask on your own are whether they have experienced and trained drivers, the length of time their business has been in procedure, or if they have some accomplishments. You can often get the solution to these concerns from the maker's website. You can research other internet sites or exterior sources to validate if the info offered on the producer's website is authentic.

Premier Aluminum Llc Can Be Fun For Anyone

Another thing you have to consider is the manufacturer's capability to generate light weight aluminum die-casting items. To put it simply, the volume of items the manufacturer can create at a provided time. Some of the essential inquiries you need to ask yourself are whether the maker can generate a higher volume or can the producer satisfy your demands.

(https://soundcloud.com/premieraluminum11)What if your company needs 10,000 items of particular machine parts from the producer within one month? You bought this amount; nonetheless, the producer can only create 5000 items of these maker components within one month (Aluminum Casting). Consequently, you will not be able to receive the quantity that you order on time

Some Known Details About Premier Aluminum Llc

Thus, it is necessary that you should inquire if the producer is carrying out an internal tooling process. Furthermore, you have to ask the maker exactly how a lot the expense of internal tooling is. Remember that the in-house tooling process, which allows you to develop unique her comment is here styles and shapes can be an additional cost.

This element directly correlates with the manufacturer's manufacturing capacity. You have to search for a producer that can ensure quicker distribution of items. Nevertheless, this should be carried out in such a means that top notch requirements are maintained. This can ensure that you can obtain your items on schedule, and you can stay clear of missing those beneficial service chances.

This implies that there are several alternatives that you can pick from. Today, consumer demands keep on altering. It appears that customers are browsing for an excellent combination of top quality, cost-effectiveness, and sturdiness. That is why it is substantially recommended that you must choose a producer that can create different sorts of light weight aluminum die-cast items.

More About Premier Aluminum Llc

A lot of typically, these aluminum die-casting products will certainly require some decors, machining, or finishing touches. Having this in mind, you need to seek a manufacturer that can execute a range of secondary finishing works when die casting is done. Some instances of completing procedures include Chromating, CNC Machining, Sandblasting, Powder layer, Anodized, E-coating, Wet painting, Plating, and many even more.

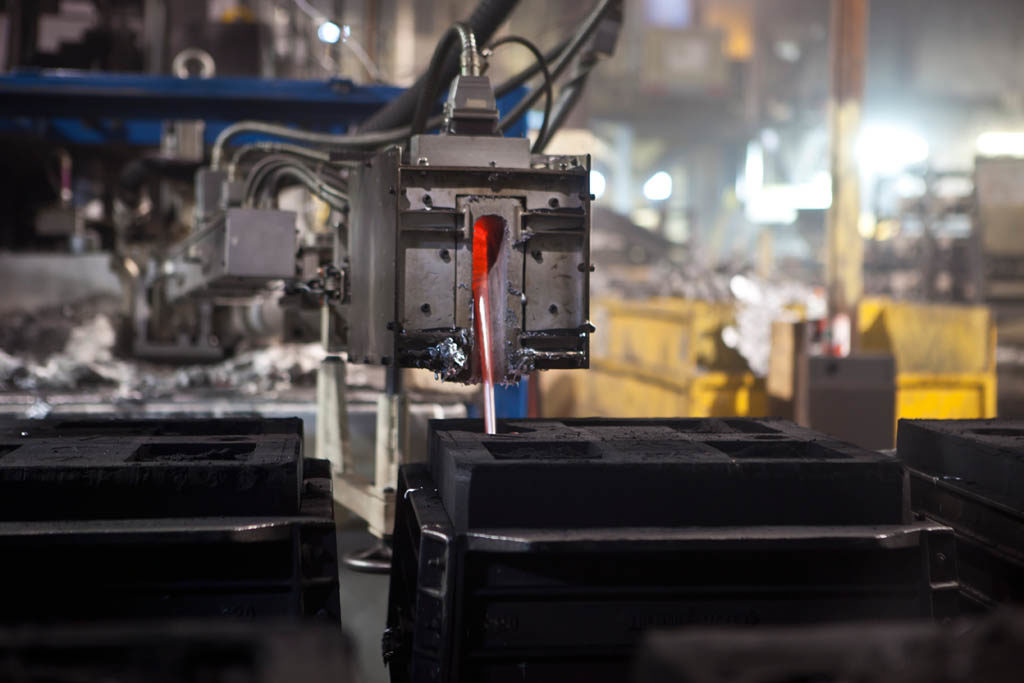

Pass away spreading is just one of one of the most cost-efficient, precise, and protean manufacturing processes on the planet moment. The process includes fitting molten significance, under pressure, into an applicable die (planet), and formerly solidified it can be expelled and ended up (if required) in a variety of means. The dies are [...]. Report this page